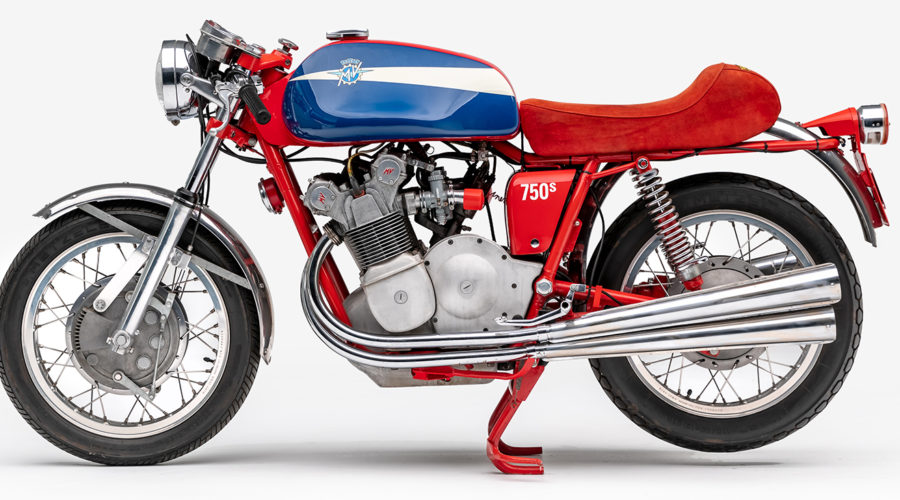

1972 MV Agusta 750 S

How do you start to write about the MV Agusta?

Do you detail the way they have dominated the world championships, do you point out that the factory’s craftsmen only make one four-cylinder bike a week, or do you merely say that this is the world’s most expensive motorcycle with the most exclusive breeding?

For years rich enthusiasts throughout the world have dreamed of owning an MV4. Their exclusivity is heightened by the makers not being interested in selling road bikes, despite the release of several 600 fours in the mid-60s.

Count Dominica Agusta, who owns Meccanica Verghera, (MV) earns his millions from his helicopter factory and runs the bike side for a hobby and prestige.

Since the very beginning of MV, a small production line has produced small capacity, old-design motorcycles to sell on the local market. But the main reason for motorcycle production has been to supply riders like Ubbiali, Surtees, Hocking, Hailwood and Agostini with the best conceivable racing bikes to re-write the history of motorcycle racing.

Only in the last year has there been a hint of the famous Italian firm coming up with 750cc road-going bikes on a regular basis.

When Giacomo Agostini visited Australia last year the businessman who brought him out, Bob Jane, pulled off a remarkable deal. He established the first MV distributorship in the world. Not only was he importing the small bikes, three versions of the 750 were coming out as well.

As everyone expected, the 750s are very expensive and the initial prices of $4500 for the standard four and up to $7000 for the production racing version were astronomical.

Since then the importer has been able to deal realistically with the Italians and the prices have been dropped to $3889 for the GT and Sport and $4779 for the SS. The GT differs only from our test model (Sport) by having touring bars and a dual seat, but the SS is a full-blooded racer and very expensive, even if Agostini tests them personally before despatch.

The bike we rode was the first in the country and we lived with it from the time it was unpacked, through the stages of running in, right up to the time when it was repeatedly hammered around the racing circuit.

When the moment came to strip the crate (which came off the ship that morning) at the Bob Jane Organisation warehouse, there was no shortage of eager hands!

Unlike other crated bikes, the MV came assembled with a seal of factory approval. The bike was beautifully packed and encased in padding designed to protect every little component.

As soon as the bike was out of the crate the battery and sump were filled and the long-awaited time came to fire up. With mechanics rushing around checking everything had been properly set up, I tickled the carburettor float chambers and pushed the right-hand button.

The motor turned over several times before there was any life – first a few “fut-futs” and then came the roar of all four cylinders alight.

But the expression of thrill had turned to horror as soon as the initial rev blast died down to a fast tickover and a loud metal to metal whirring noise nearly drowned the exhaust. The engine was immediately switched off.

All kinds of ideas were thrown around the gathering. Maybe the oil pump. has to be primed, maybe the engine has to be turned over by hand to circulate the oil … maybe, maybe, maybe. But another short run located the noise in the top end, which meant either the valve gear was running dry (very expensive), or the complex valve gear makes that kind of noise anyway.

The consensus of opinion was to carry on; the factory would have warned of any likely troubles and the straight-cut cam drive gears must create a fair clatter anyway. A quick phone call to the Ferrari importer (those V12 engines have gear driven overhead cams) reassured everyone that the noise was natural and nothing to worry about.

We did not know at this stage how much quieter the engine was to become, but you can understand the apprehension about running a $4000 engine when it could be damaged.

Within the next couple of days every nut and bolt had been thoroughly sized up and discussed before the red-painted beauty was fronted up for the scrutiny of the registration authorities.

That’s when it started. Instead of a quick check of engine numbers and legal requirements, everyone wanted to know more. “How fast does it go?” “How much does it cost?” “Do you think it’s value for money?”

Taking a bike this heavy and expensive on to the road for the first time is enough to put the shivers up anybody, and the clip-ons and rear footing didn’t encourage initial security either. But after a few runs around the block using first to third gears it was out into the traffic and on with the job.

From that moment on we could never forget we were driving an MV – the world’s most expensive, most famous and most exclusive motorcycle. Everywhere we went heads turned, cars flashed their lights, crowds grew and never could the rider feel out of the public gaze.

Slowly but surely and ever-so-carefully the miles built up on the speedo, and so did the speed and revs. By the time 500 miles had been covered the performance was up to more than 80 mph at 6000 rpm.

As the mechanical noise lessened we must admit being initially disappointed with the bike, which seemed to have a delightful flat power curve from tickover to six grand but the power available at that speed was slightly down on a Honda four.

If the output continued proportionately, by the time the revs were around to 7900 (maximum power) nothing terribly exciting looked possible. Could the MV be a huge let-down?

When around 800 miles were on the clock the occasional blip to 7000 rpm was wound on – and that’s when things started to happen. Over six grand the rider can hear the inlet and exhaust systems take on a completely different sound; they begin to resonate, a deafening, howling roar from the four mufflers announces a tremendous power surge as the engine comes on cam.

When more than 1000 miles were behind the MV, the motor was freely revved again, again and again, until it became clear that all the parts had not only bedded down properly but had freed up beautifully and were ready to give their best.

With the appreciation of the power curve from about 6000-8000 rpm came the realisation that the complex top end maintained complete control of the valves no matter how hard they had to work. We frequently revved it to more than 9000 and enjoyed the occasional burst to 11,000 in the gears. The engine responded unfalteringly, but our natural mechanical respect kept the revs down to about 8500 for most of the test.

Due to the single seat, the clip-ons and the rear footrests, the riding position is naturally a racing one; in fact it is impossible to sit up while both hands are on their grips.

The right foot gear pedal and left foot brake pedal swivel from the pegs so their movements are perfect.

Up front are dark brown, large diameter grips, and the control levers require only a very light touch to do their job.

The contours of the seat and tank complement a comfortable racing crouch, allowing the rider to sit normally and let the wind pressure on his chest take the weight, or drop down on the tank to reduce frontal area to the minimum.

Unfortunately, the petrol taps are not paired. The left one faces backwards and the right one faces forwards for off. They both have to be turned down for on, and through a further 90 degrees for reserve. No choke is fitted, and the mixture has to be enriched by flooding the two outside float chambers, the only ones really accessible.

Turning the top-mounted ignition key one click brings on the red generator warning light and everything is ready. On the right-hand switch cluster is a small button for the starter which turns a few times to bring the engine to life.

The initial burst is followed by the motor nearly cutting out as the fuel from the flooded carburettors is finished, and it’s sometimes necessary to use the starter motor a few times to maintain firing.

Before the bike can be ridden down the road it has to be warmed up or it will just cut out. The procedure is straight out of the racing pits. The rider sits on the bike blipping the throttle to a few thousand revs until the cylinder head and inlet tracts have warmed.

The motor needs a few revs at takeoff, as the bike is heavy and high geared for what power is available at tickover.

When warm the motor idles at a very reliable 1000 rpm with the slight whirring noise of the top end nearly drowning what little exhaust note exists. Pickup is uniquely immediate – an exact reflection of the MV’s racing heritage.

Around town less than 6000 revs are necessary. There is plenty of power low down, and the fuel consumption stays at just under 45 mpg.

Undoubtedly, the worst point in riding this 750 through town traffic is that once the clutch has warmed, neutral becomes very difficult to select. We re-set the clutch thrust and handlebar lever adjusters with great care after running in and even tried different settings later on, but the inconvenience of having a box that continually shifts through neutral on to first or second remained.

Though neutral is hard to find the five gears come into play effortlessly with or without the clutch. This feature, together with perfect spacing between the ratios, enables the revs to be kept within the power band at all times.

On poorly maintained city streets the suspension is hard and even the softest setting on the back end transmits a few too many bumps through the seat.

But using only the first three gears around town certainly doesn’t show up the good points of this race-bred bike. It needs fast, empty roads.

Revving the motor to 9000 rpm in the first three gears gives about 60, 83 and 102 mph. As fourth hardly pulls above 8000 its maximum is 117 mph with top acting as an overdrive that can only be revved out on a long, long road.

Keeping the speed within the limits of the power band gives exhilarating acceleration between 40 and 115 mph which is where most of the MV’s performance lies. Though the bike can be ridden above and below those speeds it does so without the kind of blistering performance that is synonymous with an MV4.

Even with more than 500 lb to manage, the handling defies criticism. At no time does the rider feel the bike is too heavy to be thrown around. The riding position makes him crouch low and around the tank. An MV rider feels he is part of the bike.

Once moving at speed the racing crouch is adopted naturally, and everything happens just right in that position. The wind pressure is relieved as the knees and arms are tucked into the tank and the head sits on the tank with the wind whistling over the top of the instruments and hitting just the top of a full face helmet.

Though the polished alloy knob of the friction steering damper lurks up between the instruments in the rider’s view line, at no time is it needed, nor can a snaking action be provoked to create a situation where it might prove useful.

Unfortunately the centre stand does a great job of grinding itself away on fast bends and if it is removed the bottom of the exhaust clamp receives the same treatment. The ground clearance is more than eight inches and everything is tucked up tight on the bike, but the reason for the grounding is quite clear – the roadholding is so good that the bike is pushed down to extreme angles with ease.

If nothing were in the way, the MV could be leant over till the bottom frame tubes were being ground away!

Since we expected a four leading shoe Fontana front brake to work well we were not surprised at the way a fistful of lever can be squeezed at more than 100 mph and tyre squeal held right down to 10 mph!

The Fontana unit is nothing like the four leading shoe brake fitted to the Suzuki 750, where a degree of self servo grab was felt with fade and drum expansion coming in early. Due to the Italian brake using very hard linings, the lever has to be applied with different stages of pressure to bring about varying amounts of braking efficiency. No self servo is evident. Fade is so small as to be irrelevant. It is easy to understand why Agostini still insists on using this kind of front stopper in preference to one or two discs.

The rear brake is of MV manufacture and again above criticism. We proved it beyond reproach by braking from more than 100 mph for a 30 mph bend by just using the left foot. Again like the front, hardly any fade and expansion and always plenty of feel.

The Metzeler tyres fitted to the 18 inch rims handled the test without protest.

Since a lot of our readers will want to know what the top end speed of the MV is, we will describe our speed testing in detail.

With full acceleration (up to 8000 rpm) the first three gears run to 54, 75 and 98 mph. Fourth gear will only pull 8000 which gives 117 mph. Selecting top will let the revs fall back to 7400 – a drop of 2 mph to 115 mph. Unless perfect conditions are available those are the top speeds.

This clearly indicates the bike is overgeared but since it is shaft driven with no alternative crown to pinion ratios that is the way it stays. On a long, straight road when everything looks perfect top gear can be revved out gradually till around 122 mph has been achieved (7800 rpm). If we had had more room to play with we could have let the bike go on revving and possibly topped 125 mph (7900 rpm)

Acceleration suffers with the high first gear. With such a heavy bike we did not expect to lift the front wheel so the engine was revved to 7000 and the clutch let out. Instead of the rear wheel breaking away the tyre digs in, the revs drop to 3000 and acceleration falls right off until the revs creep up to 6000 and bring the bike on its power band.

Even immediate declutching once everything dug in proved fruitless, as the clutch is a bit of a beast when warm (this kind of treatment really hots it up) and is either in or out with nothing in between. With lower gearing we feel the acceleration times has 5 seconds potential for 0 to 60 mph and 13.2 seconds for the quarter mile.

Slow for such an expensive bike which is supposed to be developing 76 bhp? There’s a sound reason.

The transmission is by gear drive to the clutch (that eats a little power) and after the gearbox the drive has to go through 90 degrees for the rear shaft and another 90 degrees for the rear wheel.

So much power is lost at the crown and pinion that the rear casing has fins for air cooling. This is a good thing for it gets very hot when the bike is working hard.

Although initial acceleration and top speed are not shattering, the mid-range acceleration is, and this is what matters on the track where the MV is king.

Other characteristics include a very powerful headlight (the same as is fitted to the Ducati 750), rear units which are adjusted by a built-in lever, a silly little horn and a generator which does not put out enough juice to balance the ignition discharge till 2000 rpm is reached.

After a few weeks of thorough testing we came to the conclusion that the bike has the best high speed manners conceivable. It is, in every sense of the word, a “race-bred” bike, offering perfect handling, braking and roadholding, with an exclusive power unit producing terrific mid-range acceleration. In short, a sports bike that is a racing iron made civilised.

By Derek Pickard. Two Wheels, October 1972

Tech and Spec

At the heart of the 750 Sport is an extremely complex crankshaft. Instead of a simple one-piece casting with machined main and big end journals to make plain shell bearings, the MV has an all-roller built up crank. A total of six roller main bearings support the shaft either side of the big ends, which each have two separate flywheels. The extra main bearing is in the centre where the gear drive is taken off for the cam drive gear train.

The two outside main bearings are conventional and pressed on to the ends of the shafts, but the inside four are built up around the shafts by positioning the rollers and then adding the split outer races, which look like thick shell bearings.

This means the mains are very easily replaced, but the one-piece rods and their bearings call for the dismantling of the crankshaft – an exacting task to put it mildly.

Instead of the crankshaft being supported in either the Japanese method (horizontal splitting), or the British method (vertical splitting) it is located in what initially looks like the cylinder base. This is a unique feature which makes the MV motor like no other.

The cylinder base, or more exactly, “crankcase lid”, is a huge casting which has six lugs that clamp around the main bearings. This lid also holds the 12 studs which rise up to the barrels and cylinder head. The entire engine is bolted on to a crankcase lid which sits on the one-piece crankcase (that is nothing more than an oil tank) held by a dozen studs.

With the drive to the distributor and clutch by angle-cut gears, when an owner wants to examine his engine he merely has to undo twelve small nuts and lift out the internals, leaving the transmission and crankcase intact. This way instant accessibility is gained to the bottom end. For all its complexity the MV4 is a quick engine to dismantle.

Starting at the crank and working upwards there are a total of three gears that rise up to drive the overhead cams. These are mounted on roller bearings and held in a single case that can be withdrawn from the crankcase lid by removing two screws.

The barrels are made in two pairs of two and are aluminium with cast iron liners. Solid alloy is used for the cylinder head gasket. The head itself is an extremely complex one-piece casting.

Both camshafts run on four needle bearings each and have their gears bolted on to central flanges.

Tappet adjustment is carried out by fitting different thickness shims on top of a large diameter valve cap which also acts as a wearing surface for the rotating cam lobe. To prevent excess valve guide wear, the top of the valve (where the shims are fitted into the cylindrical cap) has an extra guide. The rev counter drive is taken off the inlet camshaft.

Two compression and one oil ring are fitted to the pistons which have solid skirts. The power unit itself has a staggering total of 21 bearings, a number which most makes cannot approach even when the bearings in the transmission are taken into account.

Power take-off to the clutch is achieved by angle-cut teeth on the right hand flywheel of number one cylinder. The clutch is of conventional design with six·friction and six plain plates compressed by five coil springs that are held in place by caps and screws.

The five-speed constant mesh gearbox and shaft drive gears reveal nothing startling, with the only unusual feature being the mounting of the fan pulley which connects to the underslung electrical dynastart unit. Due to an extra internal shaft which drives to the outer clutch drum, the dynastart is constantly geared to the crankshaft despite what is happening to the clutch and gears.

This dynastart is obviously an afterthought in the design as its underslung position is extremely vulnerable. The two drive belts are unprotected and quite open to whatever is thrown up from the front wheel.

Ignition is by a car-type distributor which has the rotor button, cap, leads and plug connectors from a Porsche 912. MV have always used this seemingly old method of obtaining sparks and still maintain it is the most reliable.

The four 24 mm Dell’Orto carburettors look quite small even with their air trumpets. They are rubber mounted to the cylinder head but have no choke, no air filters and are also vulnerable to dirt entering their tops due to extra large holes for the throttle cables.

The bulbous sump holds eight pints and a replaceable filter which also lubricates the transmission.

Despite its complexity the engine is only 17 inches wide and is finished in what initially looks like rough-cast aluminium, but further inspection reveals to be a blasted surface. At no time during the test were any oil leaks seen from any part of the motor.

Three huge bolts hold the power unit to the frame which gains its rigidity from the sheer strength of heavy wall tubing instead of modern triangulated design. The frame is rather heavy as a result, even though it has only two bottom tubes and a single top tube. Finished in traditional Italian racing red it has the job of exhausting the engine breather, which leaves the motor under the distributor by a large diameter plastic tube, enters the frame near the steering head and releases the gases through a hole cut in the tube under the motor. Taper roller bearings hold the steering and swinging arm. One of the large diameter swinging arm tubes also holds the shaft drive.

The rear-set footrests are directly mounted on to the tubes and the mounting points also hold the mufflers.

At the front end of the bike comes a long list of the best components money can buy: Borrani rim, 10 inch Fontana four-leading shoe brake, Ceriani forks with five inches movement, CEV headlight, alloy plate-mounted Veglia instruments, mounted stainless steel guard, friction damper and fabulous looking Tommaselli clip-ons and controls. This name is new to the Australian motorcycle scene but we can confirm it as standing for the best products we have ever seen fitted to a bike. The welding, machinery and plating of these clip-ons is excellent and their big gum grips and safety sealed extensions are sensible fittings.

At the back of the beautifully shaped and trimmed single racing seat is the word “Emmevi”. This is not the signature of the craftsman who made it, but the cable word for the makers – MV (“Emmevi”) – get it? The red seat swivels to reveal the tool kit which is held in a roll and clamped to the seat base, but fiddling the tools back in the bag in the position that allows them to be refitted is a Chinese puzzle.

Before meeting this sportster we had not heard of Zenith rear units before, but can confirm them as being worthy of the bike they are fitted to. Their built-in levers permit them to be adjusted to any of the three settings in seconds.

The overall impression after a good look over this superbike is one of meticulous attention to detail.

The Image

The beauty is finished in stainless steel, chromium plating, polished alloy, rough cast alloy and above all Italian racing red.

This dominant colour covers the frame, rear units, side covers, seat, stands, horn, triple clamps and petrol tank. The only exceptions are the side panels of the tank which are blue with a white flash that mounts the MV badge.

On the top of the petrol tank and always in full view is a large white-bordered rectangle. On the left are the three colours of the Italian flag, then the eye encounters the words which translated mean “Thirty-four times champion of the world”. Beneath the script are 34 five-cornered stars, one for each championship.

Maybe, if Agostini had not visited Australia last year and the Press and television not given him and the MV so much publicity, riding this 750 would be more peaceful. But everybody seems to know just what the MV badge stands for which makes a rider’s life a plagued one. He is besieged by onlookers and inquisitive admirers.

What Makes the MV?

Had this four-cylinder bike entered the country under the name of an unknown Italian constructor like “Lavernelli” things would be different.

There would not be racing team overheads to push the price up – after a good look at the machine we feel it could be sold for around $3000. This would still make it the most expensive bike around but it would lack the glamour of the famous-name exclusivity.

A road test would probably praise the handling and finish, but would criticise the lack of bottom and top end performance. Testers would describe the layout with its car distributor and antiquated generator as “in some ways old-fashioned”. The bike would sell in very small numbers for although its boulevard performance is as good as other 750s, the lack of modern road refinements would go against it. The “Lavernelli” would become a rarely seen and rarely talked about eccentric’s plaything.

But, the fact is that the badge on the tanks says MV, and an MV it is right down to the last nut and bolt. Because of its name and its fabulous history this 750 will automatically take a position on top of the ladder, without any production racing successes or even proof of worthiness through mass ownership. Price and name alone are all-conquering.

Our time with the MV Agusta 750 Sport was a long and involved one. It was a welcome break from the usual mass-produced machinery, and when we tested it we knew it would be the only time an MV4 would be ridden to the limit in Australia. We will remember our relationship with the world’s most expensive motorcycle as one great big dose of “exclusivity”.

Inside the MV Four

The layout of the famous MV Agusta four cylinder engine is like no other motorcycle powerplant. It is stronger, more reliable and has a vastly superior operating life as well as being instantly accessible.

Our diagrams show where the engine gets its strength and dependability. Basically a combination of bearings in every conceivable position, generous proportions of each component and complete absence of chains is the formula to the MV success.

The crankshaft is supported by six main bearings of which the central four are built up by split outer races. The nine-piece shaft (14) is pressed together and only complete dismantling can enable the roller big ends to be replaced. Instead of being held by horizontally split crankcase clamping, the crank is bolted up to a huge cylinder base-cum-crankcase lid casting (21). This huge alloy casting has main bearing clamps reaching down like that in a car engine with split caps (19) to hold the bearings (9 and 11).

This casting also holds the gear train drive to the camshafts. Again this little, and in some ways insignificant, part of the engine gets the full treatment of strength in construction and ease of access. The three gears (15, 16, 17) are pegged (68) on to roller bearings (66) which are locked by end caps (7, 20) into a one-piece casting (12). This enables them to maintain their timing in relation to each other and be removed for examination as a unit by removing only two bolts (9, 13). Wear is minimised by the use of the bearings and the different sizes of the gears.

The cylinders are cast in two pairs (1) which are interchangeable and have cast iron liners (2). For each cylinder pair either side of the gear tunnel there are six waisted studs (22) which reach from the base casting up to the head. The aluminium head gasket comes in three pieces (3, 4). Small ends are plain bushes which support the wedge-head, three-ring, solid-skirt pistons (27).

For a single·component the cylinder head (5) must be the most complex of the motor. The top gear (17) of the gear drive train engages with the two camshaft gears (42) that connect to their shafts by bolts (43). Both camshafts run on four needle roller bearings (53, 54) with the rear inlet cam (1) driving the rev counter take off shaft (63). All valves have double coil springs (24, 25) that are held by split cotters (27). To obtain a valve clearance set up the top of the valve has a cap (31) in which can be placed shims (32) of different thicknesses. These caps run in bushes or top guides (28). Removal of the cam covers (47) permits the clearances to be measured and reset after removing the cam bearing caps (52, 54) to allow the shims to be removed or replaced.

The only role the crankcase casting plays is that of an oil tank and a mounting point for the base casting (21).

In all, the engine has a staggering 21 bearings, 10 of which are on the crankshaft.

Falloon: The Classic View

There is no more hallowed name amongst the Italian motorcycle marques than that of MV Agusta. The testimony is in the total of 38 individual riders’ World Championships and 37 manufacturers’ World Championships over the twenty-five year period between 1952 and 1976.

During that time MVs won 270 World Championship races, an astonishing feat unlikely to be repeated ever again, and the spin-off was a limited number of hand-built street bikes, headed by the magnificent 750 S.

The first four-cylinder MV Agusta street bike appeared in prototype form at the end of 1950, less than a year after the 500cc four-cylinder racer made its debut. In 1949 Count Agusta persuaded engine designer Piero Remor to leave Gilera and the new engine was virtually identical to the Gilera design.

To appear different, and avoid legal liability, the first racing MV Agusta four incorporated shaft drive and torsion bar suspension, these features also appearing on the R19 Turismo road going prototype.

The R19 was never destined for production but by 1966 Honda posed a threat in 500cc Grand Prix racing and MV Agusta replaced their venerable four with a more compact triple. Rather than waste the production facility, Count Agusta then decided to make the four available as an expensive limited edition street bike. This time it was a 600cc version of the same engine producing a claimed 52 horsepower at 9000 rpm. Weighing 221 kg and equipped with shaft final drive, the 600 was created as a touring machine so that customers wouldn’t be tempted to convert it into a four-cylinder MV racer. The 600 was also extremely ugly, the front dominated by a large rectangular Fiat car headlamp.

Despite the rather unfortunate styling, the 600 was quite an innovative machine. Not only was it one of the first across the frame fours and also included an electric start and a pair of cable-operated Campagnolo twin front disc brakes. But such an idiosyncratic and expensive machine (every buyer was entitled to spend a week at the factory learning how to ride and service it) had a very limited market and in 1970 the more sporting 750 S replaced it. This time MV got the styling right, and despite the shaft drive the 750cc engine offered real performance.

The 750 S was essentially a bored (65 x 56 mm) 600 but with its bright new colours and sculptured tank looked considerably more sporting. The engine, fundamentally the old 500cc Grand Prix four from the 1950s, dominated the 750 S and while initially appearing massive and brutal, close-up the individual components had an intricate, almost delicate character.

Inside it was a masterpiece of precision castings, gears, needle and ball bearings. A matched set of three straight-cut gears running between the interior cylinders drove the two double overhead camshafts, while the pressed together crankshaft ran in ball bearings and was held in a separate cylinder block sub-assembly bolted to the main engine casting. A carry-over from MV racing practice, this not only supported the crankshaft, but it also eliminated the need for complex and intricate casting/machining operations in such a limited production engine.

While other production four-cylinder engines hung the alternator and ignition points off the ends of the crankshaft, the widest part of the MV engine was the outer cylinders. An automotive-style Bosch starter-generator fitted behind the engine sump with an automotive Bosch ignition of a contact-breaker and distributor. With four Dell’Orto UB24mm carburettors and a 10:1 compression ratio the power increased to 66 horsepower at 8000 rpm.

The chassis was also improved over the 600, a massive 230 mm Grimeca double drum brake on the front replacing the ineffective mechanical discs. The suspension included a 35 mm Ceriani front fork and a pair of Sebac shock absorbers, while the wheels were 18-inch Borrani. The wheelbase was a short 1390 mm, but with a dry weight of 235 kg the 750 S was still very heavy, mostly due to the sand-cast engine crankcases and cylinder head (because of the small production runs) and the shaft final drive.

The unsprung weight of the rear drive had a detrimental effect on handling, while the short wheelbase and top heavy feeling provided the 750 MV with unique handling. As a result the MV fours never possessed the poise of other Italian race replicas and were not as successful in production racing.

Sydney dealer Brian Clarkson entered a MV Agusta 750 S in the 1972 Castrol Six- Hour race, but retired before half-distance with clutch problems, the bike smoking heavily under acceleration just prior to retirement. Clarkson also rode the 750 S at Bathurst in 1973, finishing 6th in the Chesterfield 500.

MV fours may be flawed and compromised in their execution, but the soul of these motorcycles is the wonderful engine. While providing a connection with a racing past, it also remains one of the most sophisticated, complicated and beautiful engines ever to grace a streetbike. No other motorcycle engine can replicate the sound and experience of a four-cylinder MV howling and one ride can forgive the foibles of a flawed chassis.

MV Agusta 750 S. Price new (1972) $3,889; now (fair) $80,000; (mint) $120,000-plus.

Five Things You Didn’t Know About MV Agusta

1. The founder of Agusta, Count Giovanni Agusta, produced his first aeroplane in 1907, only four years after the Wright brothers. After the war his son Count Domenico Agusta established MV Agusta as a motorcycle company and was president until his death in 1971.

2. With an agreement to build Bell helicopters under licence in 1952 Agusta became the leading Italian producer of helicopters, this providing the income for Domenico to indulge in an expensive motorcycle racing program.

3. The first MV Agusta motorcycle was produced in 1946, and was a 98cc two-stroke single known as the Vespa, or wasp. This led to a range of smaller models and during the 1950s MV Agusta was a leading manufacturer of basic motorcycles.

4. For 1974 when the 750 S was updated with hotter cams, larger valves, and four Dell’Orto 27 mm square-slide carburettors. The power went up to 69 horsepower at 8500 rpm. Although the chassis was much as before a pair of Scarab discs replaced the earlier Grimeca front drum brake.

5. In 1975 the 750 America replaced the 750 Sport but as these were so expensive many remained unsold for several years. The final four-cylinder production MV Agusta was the 1977 850 Monza.

By Ian Falloon

Ian Falloon is one of the world’s foremost motorcycle historians and authorities on classic motorcycle provenance and authenticity. He has written many books on classic and collectable motorcycles, including the definitive guide to the MV Agusta, available here.